ELECTRICAL SAFETY : Electrical safety is a system of organizational measures and technical means to prevent harmful and dangerous effects on people from electric current, electric arc, electromagnetic field and static electricity. Electrical hazards continue to threaten safety of people and property in the form of shocks, burns, injury, fire and explosion. Sometimes the fire incidents are reported due to electrical short circuits which is a very serious matter and due to ignorance of rules and regulations, this may happen anywhere at any time because, electricity cannot be smelt, heard or seen.

Contents

ToggleElectrical Safety Audit is a mechanism to examine the healthiness of the electrical installations, their protection systems and effectiveness during fault conditions. It is also a way of ensuring the implementation of various norms and provisions instructed by Indian Standards, Codes and Regulations. Electrical Safety Audit covers a thorough review of the electrical system which could identify the potential electrical hazards, operation and maintenance practices and provide recommendations to further strengthen the electrical system to eliminate/reduce the electrical/fire hazards and improve the safety of the personnel.

Why Electrical Safety Audit of Buildings is required?

Benefits of conducting Electrical Safety Audit

- The purpose of conducting Electrical Safety Audit is to examine and review the condition of the existing electrical installation and to recommend measures for further strengthening the system in order to eliminate/reduce the electrical and fire hazards due to existing Electrical Installation and to improve the safety of the personnel. The audit mainly focuses on:

- Identifying the potential electrical and fire hazards

- Boosting employee morale by providing safe working environment.

- Smoothening the operation and maintenance of electrical installation.

- Avoiding loss of properties, human life and costly equipment.

- Ensuring the compliance with relevant codes and practice, statutory rules and regulations.

- Establishing procedures and process of safe working in electrical installation.

Electrical Installations in a Typical Office Building

Substation, Transformers, Switchgear, Electrical Panels, Capacitor Panels, Distribution Board, Distribution circuits, Electrical wiring consisting of power, lighting and fan circuits including earthing, Building and Equipment Earthing, Various types of motors, DG set, UPS, Central Air-conditioning Plant, Room Air conditioner, Air Handling Units, Lifts, Lightening Arrester, Kitchen Equipment, Water Pumps, Servers, switches, PCs, printers and other IT equipment and any other equipment/s etc.

Electrical Safety Audit-A Statuary Requirement

Electrical Safety Audit (ESA) of the Building and Electrical Installations should be carried out with reference to applicable Indian Standards, Indian Electricity Rules( IE) and other relevant Codes of Practice to identify potential electrical hazards to prevent or minimize accidents as under:

- Central Electricity Authority (Measures relating to Safety and Electric Supply) Regulations, 2023- Applicable to electrical installation including

electrical plant and electric line, and the person engaged in the generation or transmission or distribution or

trading or supply or use of electricity. - CERA Para 14.2 -Save as otherwise provided in these regulations, the relevant standards including National Electrical Code and National Building Code shall be followed to carry out the purpose of these regulations and where relevant

- Indian standards are not available, International standards shall be followed and in the event of any inconsistency,

the provisions of these regulations shall prevail. - As per chapter 2-5(3), For every electrical installation including factory registered under the Factories Act, 1948 (63 of 1952) with

more than 250 kW connected load and mines and oil-field as defined in the Mines Act, 1952 (35 of 1952), with

more than 2000 kW connected load, the owner of the installation or the management of the factory or mines, as the

case may be, shall designate Electrical Safety Officer under sub-regulation (1) and having qualification and

experience specified in sub-regulation (2), for ensuring the compliance of the safety provisions laid under the Act and

the regulations made thereunder: - Provided that the Electrical Safety Officer shall carryout recommended periodic tests as per the relevant

standards, and inspect such installations at intervals not exceeding one year, and keep a record thereof in Form I or

Form II or Form III or Form IV, as the case may be, of Schedule II of these regulations; test reports and a register

of recommendations in regard with safety duly acknowledged by owner; compliances made thereafter; and such

records shall be made available to the Electrical Inspector, as and when required

- Indian standards are not available, International standards shall be followed and in the event of any inconsistency,

- National Building Code (NBC) of India -2016 : Adhering to the NBC for comprehensive electrical safety assessments.

- IS 732-2019-Code of Practice for Electrical Wiring Installations and IEC 60364: Following these standards for electrical installations to ensure safety and reliability.

- IS 3043-2018: Code of Practice for Earthing -For proper earthing and grounding practices.

- National Electrical Code 2023 (NEC) or Latest-The National Electrical Code of India (NEC) is an all-inclusive Electrical Installations Code prepared by BIS, providing guidelines for regulating electrical installation practices across the country

- IS 1646: Ensuring fire safety in electrical systems.

- Indian Electricity Rules, 1956 (as amended up to date)

- IS: 5216 Recommendations on Safety Procedures and practices in Electrical Work.

- IS: 1646-1961 Code of Practice for fire safety (General) : Electrical works

- IS: 2309 Protection of Buildings and Allied Structures against Lightning

- Any other local guidelines / bylaws as applicable.

During the Audit, the audit team should ensure that in addition to other provisions of the IE rules as per IE Act, the provisions contained in Chapter IV, (1) General Safety Requirements- Para 29 of the IE act specifically listed are complied with.

The Audit should be carried out using calibrated instruments and personal protective equipment (PPE) during field visits for inspection and data collection.

Qualification of Electrical Safety Officer

According to Chapter 1, Para 5.2 of Central Electricity Authority (Measures relating to Safety and Electric Supply) Regulations, 2023- Applicable to electrical installation, the Electrical Safety Officer shall possess a degree in Electrical Engineering with at least five years experience in operation and maintenance of electrical installations or a Diploma in Electrical Engineering with at least ten years experience in operation and maintenance of electrical installations.

Frequency of Electrical Safety Audit

According to Chapter 1, Para 5.3 of Central Electricity Authority (Measures relating to Safety and Electric Supply) Regulations, 2023- Applicable to electrical installation, Electrical Safety Officer shall …… inspect such installations at intervals not exceeding one year, and keep a record thereof .

How to conduct Electrical Safety Audit?

Electrical Safety Audit Approach and Methodology

Electrical safety Audit should be carried out by the qualified and experienced Engineers/Technicians only, having requisite licenses to carry out such works. Utmost care should be exercised while carrying out the work to ensure that no damage is caused to persons and properties. The persons carrying out the Electrical safety audit should also use all the required Personnel Protective Equipment (PPE) for their own protection.

Following steps are followed in conducting Electrical Safety Audit :

- Pre-Audit & Coordination Meeting-

Pre Audit is the first step in safety audit and exchange of information with installation representative, this mainly consists of understanding the installation and collecting the details like single line diagram of installation, electrical safety systems and verification of documents related to electrical safety should be done. These details would be helpful to the audit team in inspection & certification.

- Physical Inspection of the Electrical Installation–

During this phase, Audit team shall do thorough visual inspection at the installation. During this stage, the incoming electrical supply receiving section (Electrical panel Room/MDBs) is inspected first. Then other electrical equipment in this section are to be inspected. The technical requirements of incoming cables, ACBs, MCCBs/MCBs, DBs, circuitry, earthing system and Lightening protection, maintenance condition, loose cabling, temporary wiring, risk of electrical fire, shock potential etc., are critically looked into. This process is to be followed upto final circuits/ equipment.

- Conducting Tests and Measurements –After visual inspection, measurements and testing of installation should be carried out. Fault loop impedance, insulation resistance of cables/ circuits, polarity, phase sequence, earth electrode resistance etc., are required to assess the condition and suitability of protective switch gears.

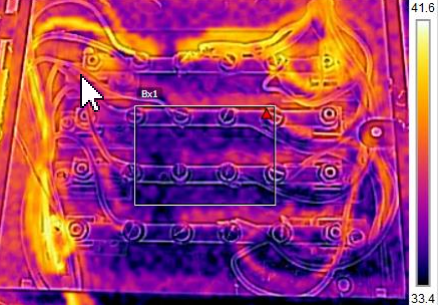

- Thermography of Installation –Thermography is viewing of thermal images of objects/connections under load through sensing of infrared radiation emitted by them. Thermography is a part of preventive & predictive maintenance technique. Thermal imaging of an electrical apparatus gives heat flow in terms of temperature gradients. Through this, present loading condition, abnormal working condition can be detected and failure/damage can be prevented.

- Discussion with Safety & Electrical personnel

- Examination & Review of Records/ Documents

- Draft Report Preparation

- Review Meeting with Management-

- Final Report Submission

Thermography of Electrical Installation

Thermography or Thermal Imaging is a process that converts the infrared energy, which is invisible to the human eye, into a visible light display. A thermal image represents varying levels of infrared radiation emitted by the objects and different levels of infra red radiation is represented by different colours and also by different temperatures .

Thermography of electrical installations is done using Infrared Camera (IR Camera). It is done to identify potential issues like hot spots, overheating, loose connections, and overloaded circuits before they lead to equipment failure or safety and fire hazards. This non-invasive technique is used for preventive maintenance, ensuring the reliability and safety of electrical infrastructure.

Scope of work of Electrical Safety Audit

The scope of work for the Electrical Safety Audit should include but not limited to:

- Study of existing safety measures, procedures and system for controlling electrical hazards being followed in the building with respect to statutory and regulatory requirements, electricity rules etc. and suggest for further measures in case of any gap.

- Verification/Checking of single line diagram (SLD) (As Built) of Electrical Installation from HT panel to Floor panels, covering transformers, main LT panel, capacitor panel, DG set, UPS Panel etc. The SLD should indicate the ratings of the equipment, feeders (wherever possible) and their present loading etc. SLD is absolutely necessary document to understand the Electrical Distribution in the building and for emergency preparedness.

- Verification/Checking of earthing layout of all the accessible and working earth pits in the building. Each earth pit should be given a unique identification number and marked on building plan.

- Earth Resistance Testing

- The earth resistance testing should be carried out to measure the earth resistance on all the earth pits and its compliance with respect to Indian Electricity Rules be verified.

- The continuity of earth strip/conductor from the earth pit the earth terminal of the respective electrical equipment should be checked and verified.

- Identification of any unbalancing of loads. The unbalancing/overloading, if any, in the electrical installation viz. transformers, LT panels, Emergency panel, Floor Distribution Panels, Distribution Boards etc shall be identified with the help of measuring equipment.

- Identification of Hot Spots using thermal camera: The hot spots, if any, in the electrical installation panels and distribution boards shall be identified with the help of thermal imaging/thermography.

- Checking Record of test reports carried out by the OEMs or their authorized representatives for proper functioning of transformers, HT/LT switchgear and proper functioning of their protective relays, failsafe interlocking of Circuit breakers

- Checking of Elevators for passenger and freight movement and passenger safety testingincluding testing of door safeties, alarms, overload protection and Automatic rescue devices (ARD), firemen control/switch, wiring in shaft and machine room etc. provided in the lift installations and gaps if any shall be identified and indicated in the audit report.

- Physical inspection of the sources of power supply viz Transformers, substation equipment, DG set , UPS installations and associated power distribution electrical installations including power supply systems & wirings for server rooms, IT equipment etc shall be done with reference to applicable Indian standards, Indian Electricity Rules and other relevant codes of practice. Any leakage of oil in transformer, capacitor banks, diesel/water/oil in DG sets, leakage of oil/refrigerant in AC plant, leakage of water in lift shaft, leakage of water over any electrical equipment etc to be checked.

- Checking provisions and sufficiency of AC services comprising AC units/ PAC systems and ventilation systems in areas housing electrical/IT equipment in 24x7x365 operations namely UPS systems, battery rooms, server rooms etc .Checking of the alternate operation of the standby fans/AC units through timers or any OEM installed logic circuits etc for proper operation.

- Verification of Records of Preventive maintenance of electrical installation and equipment maintenance, practices & documentations .

- Identification of Electrical hazards such as loose wire hanging, cables not dressed properly, broken switches, plugs and sockets etc. shall be done.

- Checking of the protection devices in up stream and down stream switchgears and their settings to ensure that the same are in the desired graded manner as designed as per the requirements of existing standards including setting/adequacy of ELCB and their ratings for earth leakage protection.

- Checking of the Lightning protection system of the building and ensuring that lightning arrestors are connected to two isolated earth pits. These pits should not be connected to electrical system earth.

- Checking of Illumination level in various working area as per standard and identifying gaps/shortfalls if any as per process/area requirement.

- Checking of the provision of electrical shock treatment chart in Hindi and local language near electrical equipment and substation. Checking the record of the training provided to the electrical staff on electrical safety, shock treatment and to handle emergencies and artificial respiration.

- Checking the log of electrical accidents maintained.

- Checking of the provision of Danger sign Boards indicating the voltage at a prominent location of electrical installation.

- Checking of the cable terminations at various panel and distribution boards to avoid phase and earth fault.

- Checking of the provision of protective guards and belt covers for all the rotating electrical equipment.

- Checking the provision of firefighting equipment and fire alarm system detectors near all the electrical installations. It is to be ensured that Fire buckets filled with free flowing sand and DCP/C02 fire extinguishers are provided near electrical substation and electrical panel locations.

- Verifying that all the workmen engaged on electrical installation work has been provided Personal Protective Equipment (PPE) i.e insulated gloves, safety shoes and insulated tools etc and the same are being used. These equipment should be periodically checked for their proper functioning.

- Verifying provision of First Aid boxes and their periodic replacement of expired medicines.

- To check the provision of insulated mats of ISI mark in front of all the electrical panels.

- To check the provision and use of proper height, strong and properly insulated ladders for the maintenance work.

- To check the provision of proper ventilation of substation, transformer rooms, electrical panel rooms and battery rooms etc.

- In addition to above, checking for any shortfalls in the existing electrical systems which impact on human and fire safety

Prerequisite documents before conduct of Electrical Safety Audit

In order to understand the condition of existing Electrical Installation during Electrical Safety Audit, the availability of the following documents shall be helpful:

- Single line diagram (SLD) of the entire existing Electrical Installation and Electrical construction drawings

- Earthing Layout of Electrical Installation

- Records of Preventive and Breakdown Maintenance carried out for the Electrical Installation

- Test Records of various Electrical systems

- Details of maintenance practice being followed in the organisation

- Details of existing Electrical Installation

- Previous Electrical Safety Audit Reports, if any

Equipment/measuring instruments for Electrical Safety Audit

The following minimum equipment/instruments are required for Electrical Safety Audit:

- 3 phase Power Analyser – To measure and analyze electrical parameters such as voltage, current, harmonics, and power factor.

- Infrared Thermography camera -To detect overheating components and potential failure points through thermal imaging.

- Earth Resistance Tester – To measure the resistance of earthing systems

- Megger – For checking the resistance of electrical insulation

- Multimeter and Tong Tester – For measurement of voltage, current, and resistance

- Safety gadgets like safety shoes, safety helmet, hand gloves

- Leakage Current detection equipment

- Any other equipment/instrument

Electrical safety Audit Report

After completion of the audit, post audit review meeting should be held with the Building engineers detailing about their observations.

The audit report should include

- The status of the entire electrical installation observed by the audit team during the safety audit. The Audit Report should include the details of all the tests carried out, Layout plans/Line Diagrams prepared, Thermal images of Thermal Camera for the hot spots, Team observations etc.

- The recommendations of the audit team for improvement in the electrical installations.

- Any other document required as per scope of work

Sample Format of Electrical Safety Audit Report

Sample Format of Electrical Safety Audit Report

Building Information

- Building Name:

- Address:

- Type of Building:

- Occupancy:

- Total Floor Area:

Electrical Load Details

- Total Sanctioned Electrical Load:

- Actual Load:

- Details of Major Electrical Installations:

- Transformers:

- Generators:

- Pumps:

- Elevators:

- Central Air-conditioning Plant:

- Fire Fighting System:

- Main Distribution Boards (MDBs):

- Sub Distribution Boards (SDBs):

- Uninterruptible Power Supplies (UPS):

- Other Major Equipment ………..

Management Information

- Management/Engineer Representative:

- Contact Information:

- Date of Audit:

- Audit Team Details:

- Lead Auditor:

- Team Members

___________________________________________________________

- Introduction

Provide an overview of the audit, including the purpose, scope, and methodology used during the audit process.

- Pre-Audit & Coordination Meeting

Summarize the pre-audit meeting, including:

- Date and time of the meeting

- List of Participants

- Summary of the information exchanged

- Single line diagram (SLD) of installation

- Electrical safety systems in place

- Documents related to electrical safety

- Physical Inspection of the Electrical Installation

Describe the physical inspection process and findings, covering:

- Inspection of the incoming electrical supply receiving section (Electrical panel Room/MDBs)

- Inspection of electrical equipment

- Technical requirements checked:

- Incoming cables

- ACBs, MCCBs/MCBs

- DBs, circuitry

- Earthing system and Lightning protection

- Maintenance condition

- Loose cabling

- Temporary wiring

- Risk of electrical fire

- Shock potential

- Photographs of key areas inspected

- Conducting Tests and Measurements

Document the tests and measurements conducted, including:

- Fault loop impedance

- Insulation resistance of cables/circuits

- Polarity

- Phase sequence

- Earth electrode resistance

Provide test results and analysis of the condition and suitability of protective switchgears.

- Thermography of Installation

Explain the thermography process and findings:

- Equipment and connections tested

- Thermal images captured

- Analysis of temperature gradients

- Identified abnormal working conditions

- Recommendations for preventive measures

- Discussion with Safety & Electrical Personnel

Summarize discussions with the safety and electrical personnel, highlighting:

- Key points raised

- Areas of concern

- Suggestions from personnel

- Examination & Review of Records/Documents

Detail the examination and review of records/documents, such as:

- Maintenance logs

- Previous inspection reports

- Safety certificates

- Compliance records

- Observations

Provide detailed observations, categorized as follows:

- Positive Findings:

- Well-maintained equipment

- Adequate safety measures

- Areas of Concern:

- Non-compliant installations

- Potential hazards

- Recommendations

List recommendations to improve the electrical system, including:

- Immediate actions required

- Long-term improvements

- Suggested upgrades to equipment

- Training for personnel

- Limitations, if any

Discuss the limitations, if any, encountered during the audit, such as:

- Areas that remained unaudited, if any

- Data or documentation not provided, if any

- Restricted access to certain installations, if any

- Time constraints, if any

- Review Meeting with Management

Summarize the review meeting with management, including:

- Date and time

- Participants

- Discussion points

- Management feedback

- Agreed actions

- Conclusion

Conclude the report with a summary of the audit findings and a call to action for the management to implement the recommended measures.

_______________________________________________

Appendices

- Appendix A: Photographs

- Appendix B: Test Results

- Appendix C: Thermal Images

- Appendix D: Copies of Reviewed Documents

- Appendix E: Audit Team Details and Signatures

Prepared By:

- Lead Auditor Name:

- Signature:

- Date:

Reviewed By:

- Management Representative Name:

- Signature:

- Date: